Join the Blanchard Team..

Apply Now

Have you ever gone to crack open your backup supply of diesel fuel, only to discover it’s acquired an unsightly dark color and a layer of muck and grime? Your first thought might be that it’s a lost cause and should immediately be taken to the nearest hazardous waste facility.

Before you proceed with disposal, however, there may be a solution to recover your fuel investment. That’s where polishing comes in. At Blanchard Energy — a division of Blanchard Machinery Company — we offer high-quality fuel polishing services in South Carolina to remedy contaminated fuel.

How can fuel polishing help restore its integrity? If you’re unfamiliar with this process, you can learn all about it in this complete guide to fuel polishing.

Fuel polishing is a cleaning process that removes water, dirt and bacterial buildup from stored oil and hydrocarbon fuel. It involves pumping the diesel fuel through a series of filters and returning it to the tank.

Fuel polishing typically draws fuel from one end of the tank. It returns it to the tank’s opposite side to minimize contact with unfiltered fuel and limit mixing. Removing contaminants aims to restore your fuel to peak quality. As a result, you can ensure it’s safe for equipment and avoid clogged filters, failure, expensive repairs and downtime.

Many fuel polishing procedures include multiple phases of filtration. They may also operate automatically using a programmed schedule. Quality fuel polishing systems use advanced filtering technologies that typically target the densest matter first.

Furthermore, highly pressurized contamination can be hazardous. It usually occurs on the suction side of a diesel fuel tank. That’s why fuel polishing systems tend to target built-up matter near this area.

If you’ve been storing a hearty stash of diesel fuel at your work site over a long duration, you might be in for a rude awakening when you finally go to use it. Over time, diesel fuel naturally degrades and becomes clogged with gums and sediment, especially when stored improperly. This is the case with any organic fluid. Without routine testing and maintenance, stored fuels become contaminated and require fuel polishing.

Attempting to use degraded fuel can wreak havoc on a commercial, industrial or marine power system. As the fuel sloshes around in the tank, sludge can rise to the surface and clog up the engine to the point of breakdown. This situation is especially problematic for standby power applications that rely on stored fuel for emergencies.

Contaminated fuel is particularly concerning for marine applications. Vessels rock around in the water, sloshing the fuel around the tank and dispersing the contaminants. Shore-based storage tanks at marinas are also susceptible to contamination from bird droppings, rust and infrequent cleaning.

Degraded fuel is a notorious cause of premature breakdowns in backup generator systems. In fact, contaminated fuel is among the top causes of diesel engine failure. The longer the fuel remains in storage, the higher the risk of an engine malfunction due to issues like:

Generally, fuel polishing is highly effective. By separating water and filtering out foreign matter, this process can help replenish the condition and quality of your stored diesel fuel. As such, fuel polishing has become an integral part of fuel maintenance for many facility managers. It helps them preserve their backup supply and save on costs.

If you store large quantities of fuel at your site for months at a time, we recommend a powerful fuel filtering procedure. Power systems depend on reliable energy sources to serve their function, so their energy supply must be in optimal condition.

Diesel fuel usually lasts six months to a year if properly maintained and stored in a cool, dry environment. Depending on how you store your fuel, you might consider polishing if it’s grown contaminated before the end of its expected shelf life.

There are numerous indicators of contaminated diesel fuel, including:

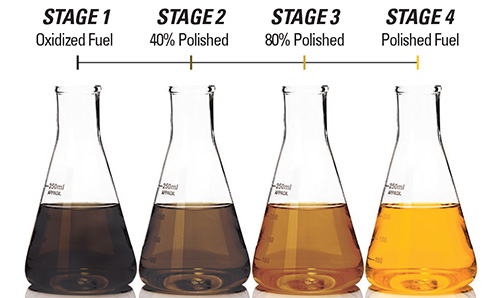

Clean, safe diesel fuel should be a yellow, red or orange hue, depending on the type and dye. It also shouldn’t be overly cloudy or hard to see through.

Spotting any of the signs listed above is typically enough evidence to verify contamination. However, you can also take a sample of your fuel and get it tested if you feel so inclined. Fuel testing is a simple, accurate way to identify microbial growth and other types of contamination.

We also recommend fuel polishing in the following situations:

When left untreated for extended periods, diesel fuel is prone to three primary types of contaminants. It’s important to watch for them in your fuel. If you detect any of the pollutants below, your stored diesel fuel is likely due for a thorough polishing.

Water may be vital for humans, but it doesn’t bode nearly as well for diesel systems, posing a risk to both fuel tanks and engine parts. Diesel fuel does naturally contain a small percentage of dissolved water, but an excess amount can harbor bacterial growth and gradually degrade the fuel.

This form of contamination is hardly visible at first because it begins with the water dissolved. However, as the fuel and water blend emulsifies, it starts to take on a cloudy appearance. Eventually, free water collects in puddles in the fuel, providing a breeding ground for various microbes. The polishing process targets water in all three forms — dissolved, emulsified and free — to purify your diesel fuel and render it safe for use.

As we mentioned earlier, diesel fuel polishing generally attacks solid particles first. It starts with the densest debris. If you notice extreme discoloration in your stored fuel, one or more of the following particles could be present:

Fuel polishing can filter out this matter from your fuel reserves, bringing it as close to its original color and function as possible.

Having microbial matter present in your diesel fuel, a condition commonly referred to as diesel bug, can lead to significant issues like the following:

Multiple types of bacterial matter can build up in diesel, including mold, biofilms and yeast. Regardless of the type, bacterial growth is often the most challenging contaminant for fuel polishing systems to strip away.

A standard fuel polishing system will only dissolve and filter out sludgy biomass created by microbial matter. Keep in mind that it doesn’t actually kill and eliminate the bacteria from the fuel tank. To accomplish true microbe removal, you’ll need to use a biocide treatment in conjunction with the fuel polishing process to destroy and extract the bacteria.

Diesel fuel polishing is a mechanical process that filters the fluid through one or more apparatuses. It uses multiple filtration stages to target and extract debris, often minimizing or eliminating the need for costly fuel additives.

While fuel polishing can vary depending on the company and its specific procedure, it often involves these stages:

Diesel fuel typically starts to degrade in six months to a year, especially in hotter temperatures. Try to have your stored diesel fuel polished at least once a year — or as soon as you start to notice substantial discoloration and debris buildup.

Consistent cleaning and refining help reduce the risk of contaminant buildup to promote efficient fuel and engine performance. Additionally, you should run a fuel test at least once each year. The results will indicate if there is a need for polishing before more costly issues emerge.

In the meantime, try to maintain optimal storage conditions for your diesel fuel to extend its life span as much as possible. Diesel fuel should be stored out of direct sunlight to decrease the risk of premature degradation. Keep it in a cool, dry space below 70 degrees Fahrenheit.

These conditions can help your fuel achieve the longer end of its six- to 12-month shelf life. Exposing your diesel fuel to water, moisture, high temperatures and other potential contamination sources can reduce its life span considerably.

Diesel fuel polishing offers a simple, efficient and cost-effective way to cleanse fuel of sediment, water and microbiological contamination. Therefore, it should come as no surprise that the global fuel polishing market is expected to hit $47 million by 2028.

From money savings to mitigating environmental concerns, diesel fuel polishing can offer a wealth of advantages for your operations. Below are some noteworthy benefits of diesel fuel polishing.

A successful fuel polishing treatment can bring your fuel to its original state or as close to it as possible. Therefore, you can recondition and use fuel that would have been disposed of otherwise. This provides savings in both fuel replacement and disposal fees.

Additionally, using clean, polished fuel reduces the risk of equipment malfunctions and failures. In some cases, diesel fuel polishing can save thousands in treatments and replacements for both fuel and equipment, potentially saving you up to 75% for an average-sized fuel tank.

Diesel fuel is classified as hazardous waste, meaning it must be disposed of as such. Getting rid of contaminated diesel fuel isn’t as simple as tossing it in the garbage or pouring it down the drain — it must be brought to a special landfill equipped to handle toxic materials.

As with any hazardous substance, disposing of polluted fuel can harm the environment. Diesel fuel has damaging effects when it seeps into the ground. It can move through soil and enter underground aquifers, which deliver water to springs and wells. Polishing allows fuel to be reused to its fullest extent, leading to fewer hazardous waste disposals.

The last thing companies need during power outages is a generator malfunction due to contaminated fuel. Shutdowns significantly set back operations and reduce productivity in industrial operations.

Diesel fuel polishing removes impurities that can clog essential engine components such as injectors and filters. Eliminating these contaminants improves efficiency and performance.

By minimizing equipment breakdowns, repairs and downtime, fuel polishing provides a more consistent power supply. A reliable energy supply ensures a smooth workflow and maximized productivity, even in the midst of an emergency outage.

Over time, diesel fuel slightly condenses while in storage, developing condensed solids that are still viable as fuel. Fuel polishing can repurpose condensed solids by extracting and converting them back into liquid form.

Fuel polishing reprocesses consolidated solids rather than just removing them. Therefore, it offers a less wasteful and more efficient way to decontaminate fuel.

Your business deserves a dependable energy source to keep your operations efficient. Diesel fuel polishing plays a fundamental role in this objective. If you’re looking for top-notch fuel polishing services in South Carolina, Blanchard Energy is here to serve.

On top of our extensive selection of power systems, we offer the necessary solutions to maintain an effective energy source for these units. Our experts commit to providing the highest-quality services for our clients. By taking advantage of our fuel polishing services, you can ensure clean, safe and reliable fuel for your equipment.

Whether you need heavy equipment, generator or marine fuel polishing services, our team can deliver the solutions you require. Contact us today to request a free quote or learn more about how our generator fuel polishing services can help you.